PFAFF 8317i

Programmable single-head ultrasonic welding unit (steel or titanium sonotrode) with innovative material feed

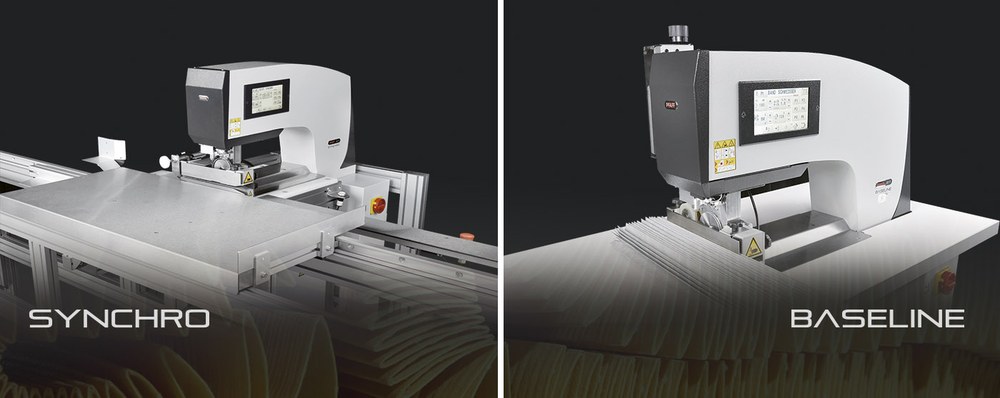

The new 8317i are offered in two versions:

BASELINE: The economical version - manual welding unit for short and not too large parts

SYNCHRO: The efficient version - modern welding unit large parts up to 1,600 mm

Features (Baseline & Synchro)

- Optimized machine setup with innovative material feed for processing pleated filters

- Safe and efficient processing of different material thicknesses up to 3 mm and fold heights from 10 mm to 50 mm without retooling

- Selection of different sonotrodes, depending on the application:

- Titan sonotrode, 10 mm wide: For processing thick materials

- Steel sonotrode, 10 mm wide: For the DUAL version, to cut off the protruding material

- Steel sonotrode, 7 mm wide: For large pleat heights up to 50 mm - Depending on the application, various anvil wheels (Ø 75 mm) and cutting wheels with different cutting angles (for the DUAL version) are available

- Seam lengths can be easily programmed via the touch panel

- Complete reproducibility of the welding processes

- Pleasant, ergonomic ultrasonic welding frequency of 35 kHz (silent production)

- Touch control panel (easy operation via user-friendly icons)

- Differential feed: Separate drive for sonotrode and anvil wheel; that means smooth, non-distorted seams

- Options: Seam cooling from above & Puller to support the feeding

Additional features of the Synchro:

- Quick setup and changeover of machine settings (filter length, pleat depth, etc.)

- New sliding table that works in sync with the welding process (self-propelled/differential work possible)

- Standard sliding table sizes: 1,000 mm or 1,600 mm (others available on request)

- After the welding process, the sliding table returns to its starting position

- Automatic start and stop of the welding process (programmable)

- Option: Ejector as removal aid

Special version with tape feeder:

- Adhesive tapes are fed reliably via the tape feed

- This enables the joining of non-thermoplastic materials

- The adhesive tape is positioned between the two end folds

Application

Specifications

Weldable material thickness: max.: 3 mm (single layer / has to be tested with customer material)

Max. height of the pleat: 50 mm (depending on sonotrode)

Welding speed: 0.1 – 10 m/min (depending on material)

Table return speed: 15 m/min. (with SYNCHRO)

Power supply: 230 V, 50/60 Hz

Working air pressure: 6 bar

Weight BASELINE: 120 kg / SYNCHRO: 325 or 350 kg

df8EhxU_ZkU

8317i