Jan 05, 2026: The new PFAFF 8317

Economical - Efficient - Highly flexible

New single-head unit with precise ultrasonic technology

Modern machine concept with innovative material guiding for processing pleated filters. The machine uses ultrasonic technology and guarantees safe and efficient processing of varying material thicknesses up to 3 mm and pleat heights from 10 mm to 50 mm without retooling. Depending on the material, customers can choose from various sonotrodes (titanium/steel) and anvil wheels. The C&S DUAL application variant (welding and cutting in ONE operation) is also available. Non-thermoplastic materials can also be joined. In that case a tape is fed via a tape feeder and positioned between the two end pleats.

The new 8317i are offered in two versions:

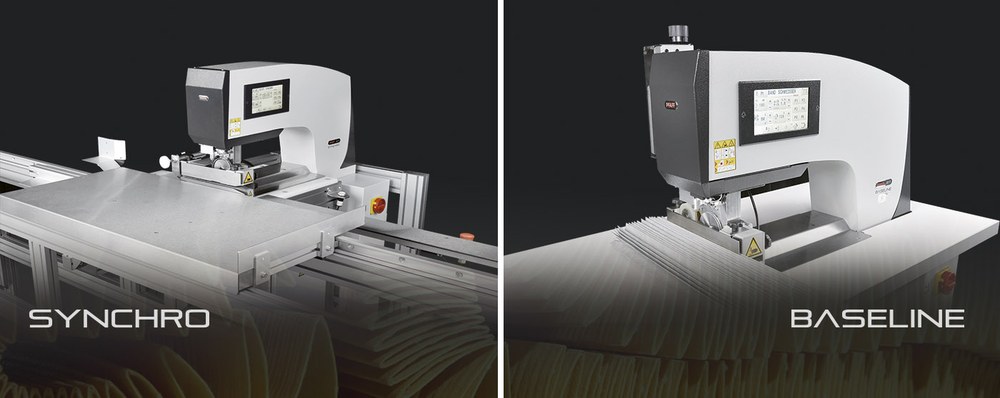

BASELINE: The economical version - manual welding unit for short and not too large parts

SYNCHRO: The efficient version - modern welding unit large parts up to 1,600 mm

Features (Baseline & Synchro)

- Optimized machine setup with innovative material feed for processing pleated filters

- Safe and efficient processing of different material thicknesses up to 3 mm and fold heights from 10 mm to 50 mm without retooling

- Selection of different sonotrodes, depending on the application:

- Titan sonotrode, 10 mm wide: For processing thick materials

- Steel sonotrode, 10 mm wide: For the DUAL version, to cut off the protruding material

- Steel sonotrode, 7 mm wide: For large pleat heights up to 50 mm - Depending on the application, various anvil wheels (Ø 75 mm) and cutting wheels with different cutting angles (for the DUAL version) are available

- Seam lengths can be easily programmed via the touch panel

- Complete reproducibility of the welding processes

- Pleasant, ergonomic ultrasonic welding frequency of 35 kHz (silent production)

- Touch control panel (easy operation via user-friendly icons)

- Differential feed: Separate drive for sonotrode and anvil wheel; that means smooth, non-distorted seams

- Options: Seam cooling from above & Puller to support the feeding

Additional features of the Synchro:

- Quick setup and changeover of machine settings (filter length, pleat depth, etc.)

- New sliding table that works in sync with the welding process (self-propelled/differential work possible)

- Standard sliding table sizes: 1,000 mm or 1,600 mm (others available on request)

- After the welding process, the sliding table returns to its starting position

- Automatic start and stop of the welding process (programmable)

- Option: Ejector as removal aid

Special version with tape feeder:

- Adhesive tapes are fed reliably via the tape feed

- This enables the joining of non-thermoplastic materials

- The adhesive tape is positioned between the two end folds