PFAFF 2083

Modern generation of high-speed sewing machines

with drop feed

An intelligent machine concept and the use of extremely wear-resistant components guarantee the quality, flexibility and sewing speed of this highspeed seamer. 50 years of experience with the production of “dry machines” and more than 15 years of experience with motors integrated in the sewing head are reflected in these high-speed seamers.

Complex assembly work is not required. The machine is supplied ready for use. The quiet running of the low-vibration machines is one of the outstanding features. The built-in drive unit, transmits the power directly (direct drive) to the machine and guarantees a 50% reduction of the power consumption compared to conventional drive units.

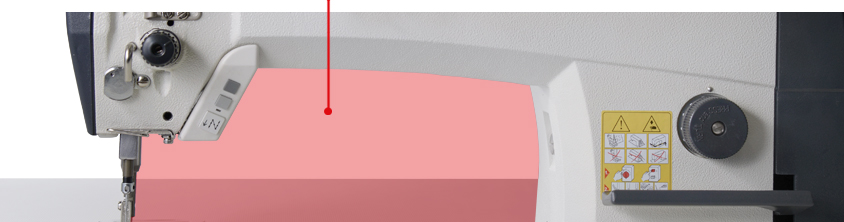

The machine works with very low thread tension settings. The needle bar stroke can be changed from 30 to 36 mm, which is an absolute requirement for sewing an extremely wide range of materials. The 300 mm arm clearance of the 2081/2083 series is unique for a high-speed seamer.

Features

- Good stitch length continuity and seam quality

- Even feed without off-setting of the material layers

- Integrated solutions for presser foot lift, backtacking mechanism without compressed air

- Automatic hook lubrication

- Robust and durable machine concept

- Easy to maintain

- Simple placement and removal due to 13 mm clearance, even for high-volume material

- 50 years of „dry machines“ (no oil-sump)

- High flexibility due to the adjustable needle bar stroke (30 to 36 mm). One machine for all material thicknesses

- Integrated bobbin thread winder

- Knife/catcher change for the thread trimming device without readjustment

- Up to 6 mm stitch length – forward and reverse (on the C-model of the PFAFF 2081/83)

Triple switch within reach of the operator: forward/reverse, 2 multi-function buttons

300 mm clearance under the machine arm

Options

Options

- Large hook (G) with 50 % more capacity than conventional hooks

- Oil free sewing (if desired) – by simply changing the hook (4,000 s.p.m.)

- The thread nipper -909/14 (option) is controlled electronically, the presser foot is raised momentarily and the needle thread is pulled through to the underside of the workpiece

Applications

General operations in most different garment sectors

Specifications

Specifications

Needle system: 134

Needle size: Version A/B 70 - 100, Version C max.120 Nm

Max. sewing speeds: Version A/B max. 5.500 s.p.m

Max. stitch length: 4,5 mm (Option: 6 mm)

Stitch type: 301 (Lockstitch)

Clearance under the sewing foot: max. 13 mm

Clear workspace: 300 mm

Connection voltage: single-phase a.c. 230 V, 50/60 Hz

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!