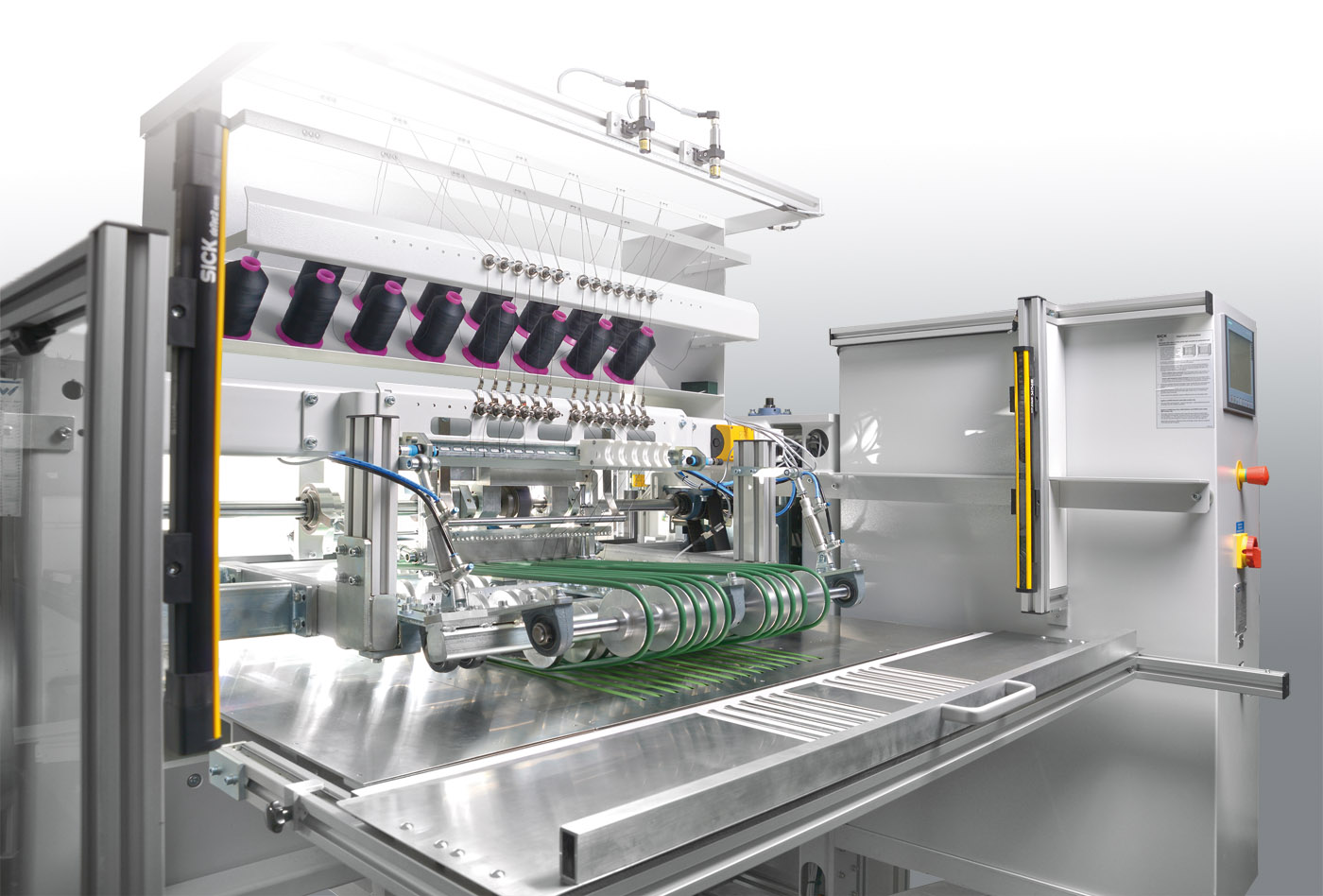

KL 950 classic

Multi-needle sewing unit (full-automatic)

Features

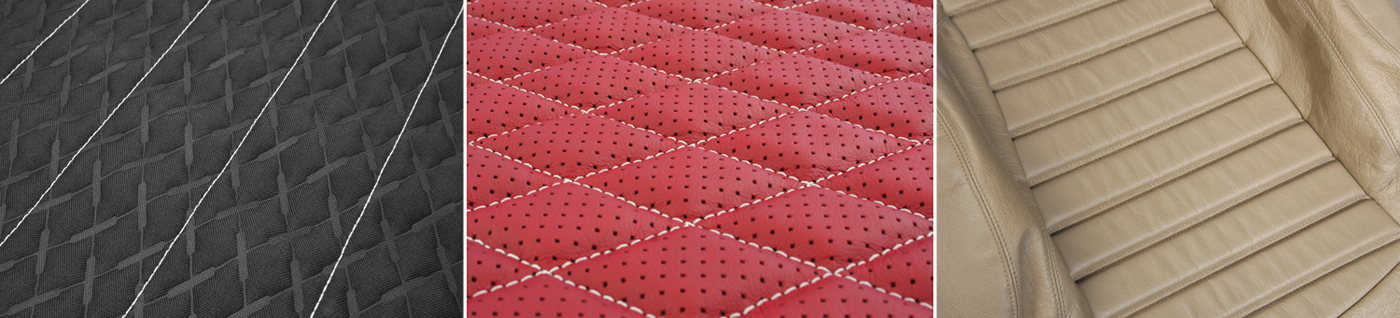

- The stitch position is at the same level with each seam, which leads to a particularly regular and precisely seam pattern.

- The fixed positions of the needle to one another ensure a supreme performance in parallel seam positioning even with ambitious materials.

- Individual pattern designs by simple relocation of the sewing tools

- 10 sewing tools

- Sewing speed: max. 12 m/min.

- Sewing unit in modular structure in steps of 600 mm up to max. 7,200 mm needle distance

- Needle distance: min. 5 mm, or upon customer request

- Condensed stitches free programmable at seam beginning and seam end

- Upper and lower thread breakage monitoring

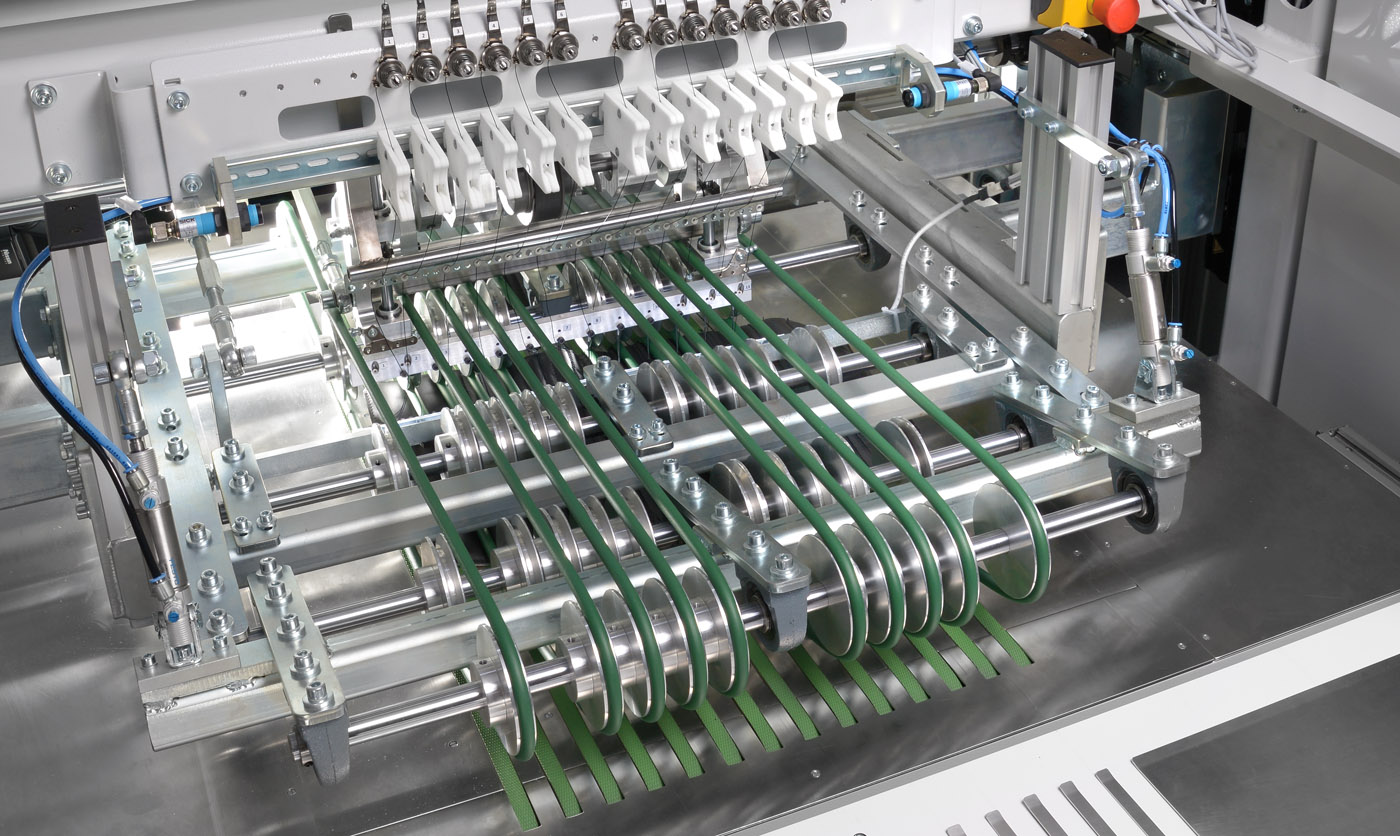

- Material transport by upper and optional lower feed by continuous transport belts

- Manual height adjustable upper transport system for adaptation to different material heights

- Processing of single cut panels as well as roll material

- Movable loading table for exact positioning of the sewing material with single cut panels

- Program and recipe management

- SPS control

- 20 thread monitors (10 each for needle- and looper thread)

Options

- Sewing-under of tapes (endless or with positioning of beginning and end of the tape)

- Sewing-under of OKE-strips or similar

- Continuous bottom feed for a correct feed of the sewing material through the entire machine area

- Integrated template guide for highest loading precision and material guidance

- Special device for sewing of sinuous lines and pockets

- Programmable stitch condensation at beginning and end of seam

- Automatic feeding of the cuts

- Stacker for the finished goods

- Conveyor system for the transfer of the finished goods

- Unwinder and rewinder to process roll material or continuous production

- Integratable longitudinal and transverse cutting system

- Feeders to control the thread tension during the sewing process

- Automatic foot height adjustment

- Integration into existing production systems

- Additional thread stand

- Laser for an exact positioning of the fabric

- height-adjustable top-transport system

- Individual needles can be switched on and off

- Thread trimmer for each thread chain (positioning adjustable)

- Stitch loosening for the sewing of sensitive materials without compression of the material

- Tape feeding system - endless from the top and/or from the bottom

- Tape feeding system from the bottom with trimming unit for the precise positioning of tape beginning and tape end

Specifications

Max. needle distance: 600 / 1200 / 1800 / 2400 / 3000 / … 6,000 mm

Max. material passage width: max. needle distance + 400 mm

Stitch length: 2.5 mm - 8 mm

Max. speed: 1,200 s.p.m.

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!