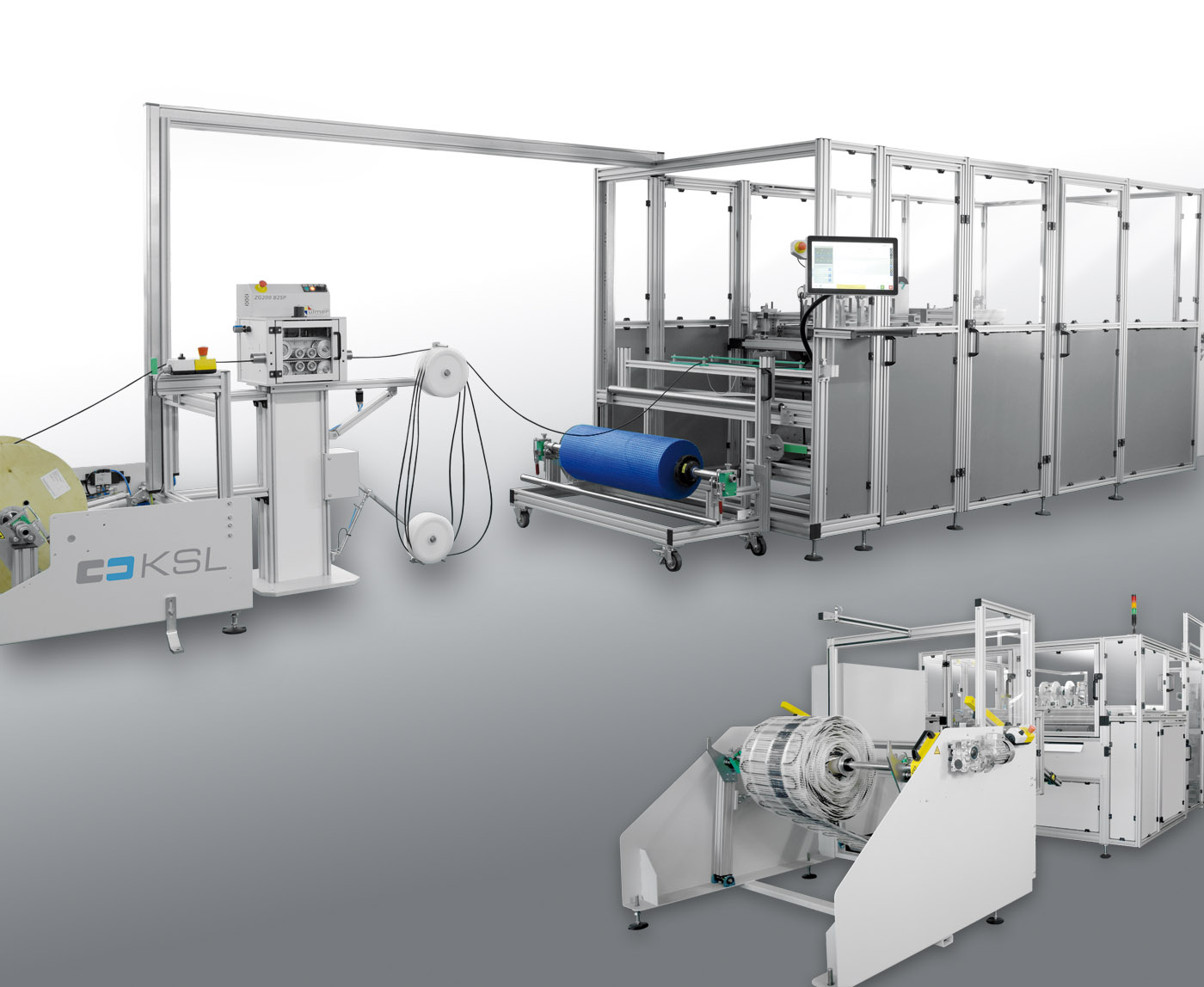

KL 421

CNC-controlled laying unit (taping) for attaching heating conductors (tubes or cables) on mesh fabrics

Features

- Components:

- Unwinding station for cable/tube

- Cable/tube dispenser

- Unwinding station for fabric

- Sewing unit

- Winding station for the finished product - Sophisticated and highly efficient system for this complex operation process

- Fully automatic, autonomous cable/tube laying and taping (also two-sided). Only the change at the unwinding and winding station is done manually.

- Cables/tubes are fixed with a tape. Max. 5 tape feeds from above and below (distances are freely selectable)

- The unit ensures a laying on mesh fabric with max. 1.000 mm width

- High-performance PC HMI with large number of service functions and freely definable user level

- For maintenance and error analysis, the HMI can be controlled remotely from a PC, laptop or smart device (using TeamViewer® as standard)

- Planning and implementation of the machine „ready to production“ based on customer requirements.

Specifications

Laying speed: approx. 20 m/min. (Amplitude: 960 mm)

Distance between the cables/tubes: from 60 mm free selectable

Max. cable/tube diameter: 8 mm

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!