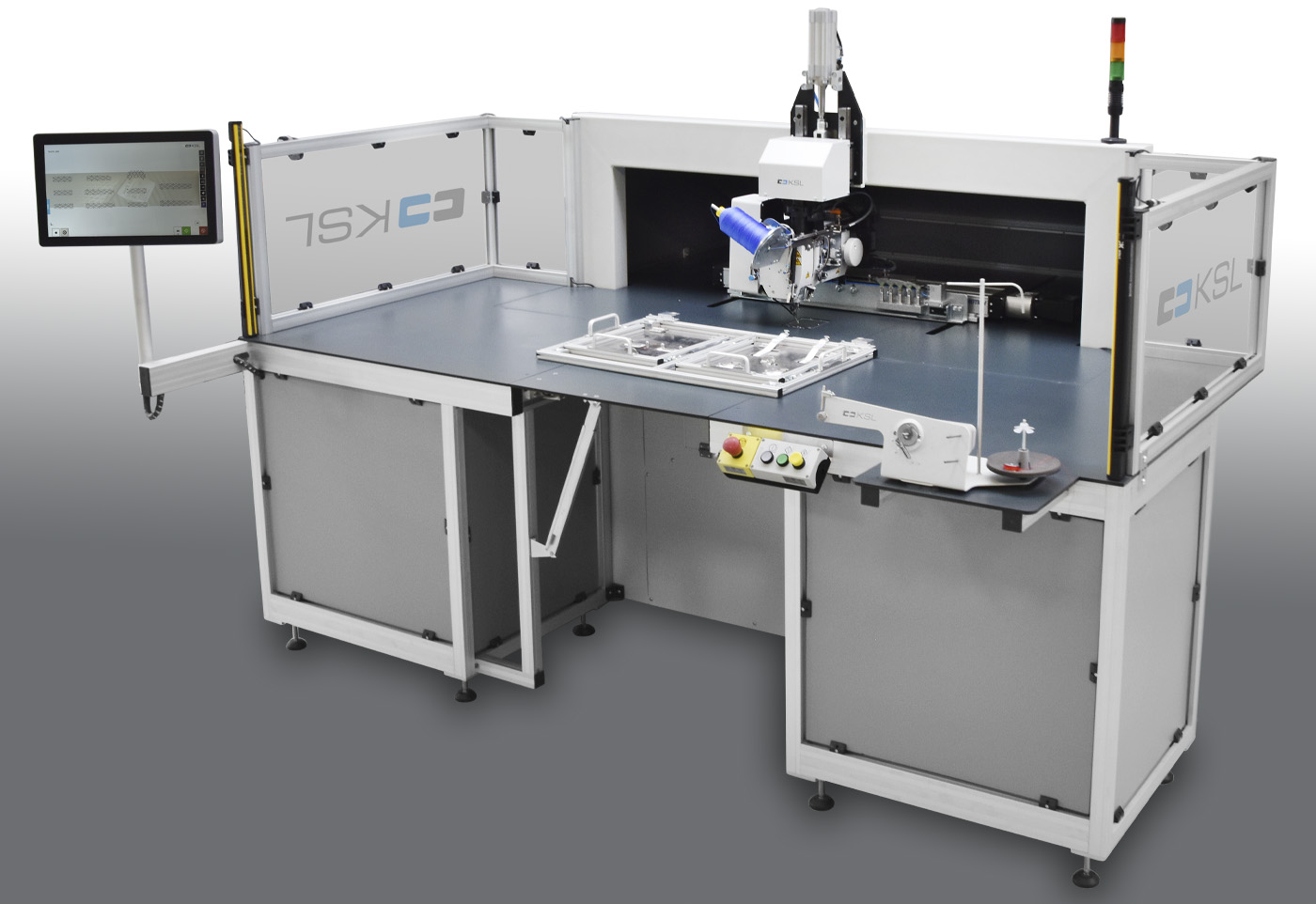

KL 352

CNC sewing unit with stationary sewing head, equipped with horizontal hook

The new KSL 352 is a solution for sophisticated safety, functional and decorative seams. The sewing head with horizontal hook, which is tailored to the machine, enables the option of a bobbin changing system. Many new technical refinements have been implemented in the KL 352, such as: Thread tension and foot height can be individually set for each seam section. These technical innovations increase process reliability and ensure a high-performance in the MULTIDIRECTONAL sewing process.

Features

New features of the KL 352:

- Residual thread monitoring on the bobbin thread

- Thread tension and thread breakage monitoring

- Thread tension and foot height can be individually set for each seam section

- Short thread trimmer at seam beginning (can be switched on/off)

- Electronic oil level monitoring, separately for lower and upper part

- Thread cone monitoring

- Thread wiper

- Vibration sensor (individually adjustable) for checking bearing damage

- Drives with EtherCAT communication instead of analog

Further features:

- Continuous material transport

- Sewing head, pneumatically liftable (75 mm) for direct access to any seam position

- XL hook (32 mm) with large bobbin thread capacity

- The touch screen operator panel ensures intuitive operation and features a modern and clear layout.

- The seam may be monitored in real time on the screen

- The automatic detection of the material clamp for added process reliability

- The sewing area is protected by a light-barrier (CE compliant)

- Template changer system for overlapping workflow

Specifications

Max. sewing speed : 2.800 s.p.m.

Stitch length: max. 8 mm

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!